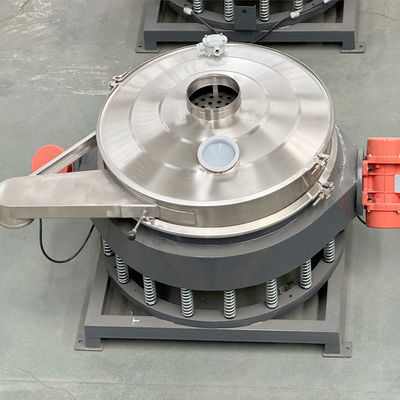

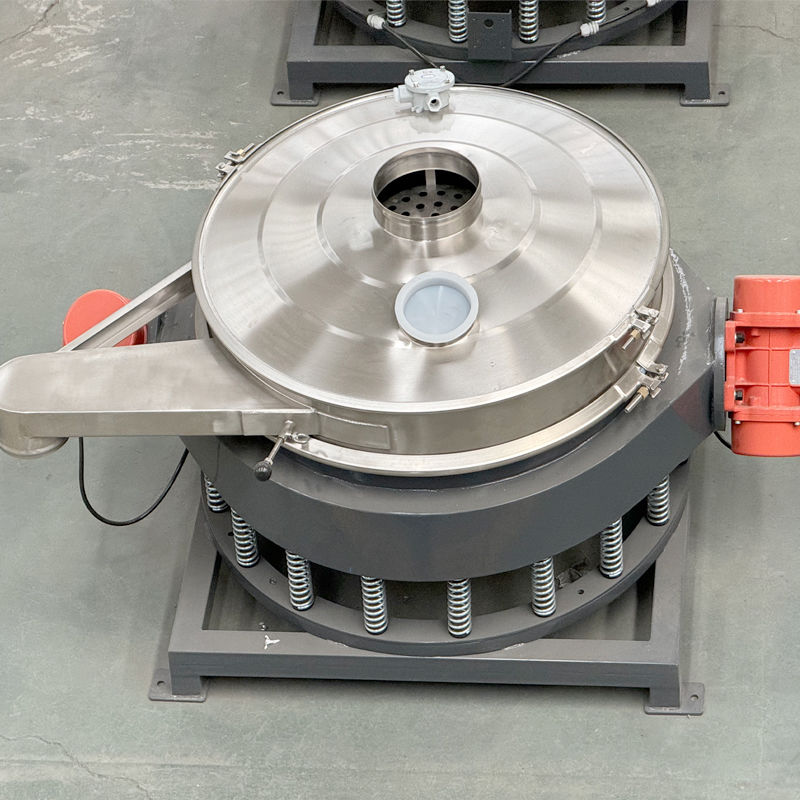

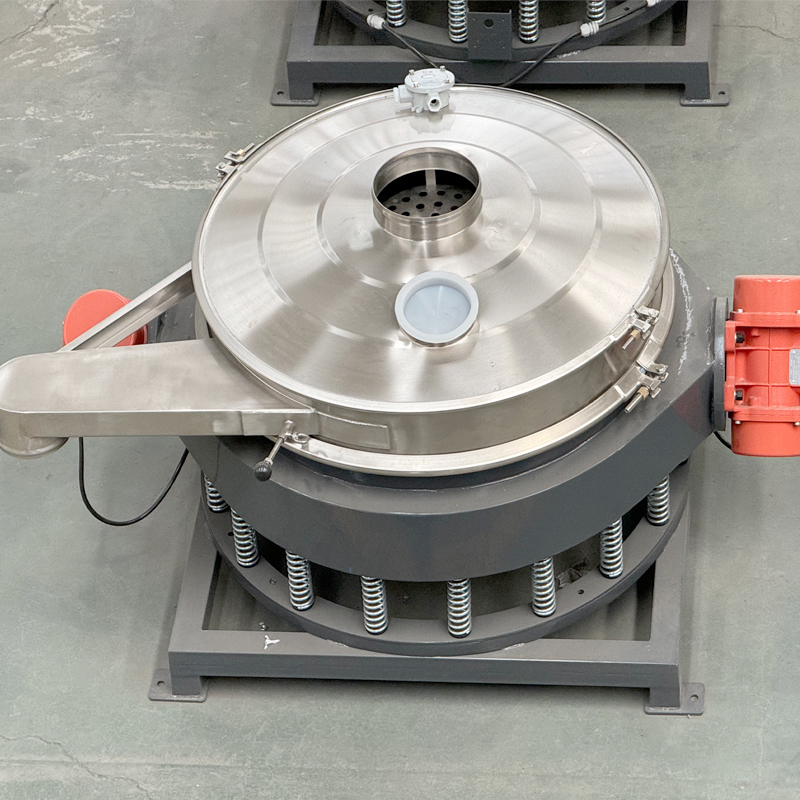

Endüstriyel eleme makinesi

Ürün açıklaması

Doğrudan geçişli titreşimli elek, kompakt ve yüksek verimli bir eleme ekipmanıdır. Ana bileşenleri genellikle bir elek kutusu, elek ağı ve titreşim motorundan oluşur. Çalışma sırasında, titreşim motoru elek yüzeyini yüksek frekanslı titreşim üretmek üzere tahrik eder, bu da malzemelerin elek yüzeyinde doğrusal bir şekilde hareket etmesine ve eleme işlemini tamamlamasına neden olur. İnce malzemeler elek ağının altından boşaltılırken, kaba malzemeler elek yüzeyinin sonundan boşaltılır. Küçük bir ayak izine, basit kullanıma ve bakıma ve sürekli çalışmaya sahiptir. Kimya mühendisliği, gıda ve yapı malzemeleri gibi endüstrilerde granül malzemelerin elenmesi ve sınıflandırılmasında yaygın olarak kullanılır.

Çalışma prensibi

Doğrusal titreşimli elek, temel olarak bir elek kutusu, elek ağı, titreşim motoru ve çerçeveden oluşur. Elek kutusu, malzemeleri taşımak ve elemek için ana gövdedir, elek ağı eleme parçacık boyutunu belirler, titreşim motoru güç kaynağını sağlar ve çerçeve istikrarlı destek sağlamaya hizmet eder.

Çalışma sırasında, titreşim motoru, eksantrik bloğun dönmesiyle bir uyarma kuvveti üretir ve elek yüzeyini doğrusal bir şekilde yüksek frekansta titreşime tahrik eder. Malzemeler besleme portundan elek yüzeyine girdikten sonra, titreşim kuvvetinin etkisi altında, ince malzemeler elek ağından geçer ve boşaltılırken, kaba malzemeler elek yüzeyi boyunca sonuna kadar doğrusal bir şekilde hareket eder ve boşaltılır, böylece verimli eleme ve sınıflandırma sağlanır.

Ürün Özellikleri

Yapısal olarak, çeşitli üretim hatlarına esnek bir şekilde kurulmasını kolaylaştıran, küçük bir ayak izi ile kompakt bir şekilde tasarlanmıştır;

Performans açısından, yüksek eleme verimliliğine ve büyük işleme kapasitesine sahiptir. Titreşim motorunun parametrelerini ayarlayarak, eleme etkisi hassas bir şekilde kontrol edilebilir;

Kullanımı ve bakımı basittir, elek ağı değişimi uygundur, bu da duruş süresini azaltabilir;

Uygulama alanı geniştir, çeşitli granül malzemeleri işleyebilir ve iyi bir sızdırmazlık performansına sahiptir, bu da toz dağılımını azaltabilir ve temiz bir üretim ortamı sağlayabilir;

Sürekli çalışmayı destekler, üretim verimliliğini etkili bir şekilde artırır ve işçilik maliyetlerini azaltır.

Ürün parametresi

| Model |

Güç(kw) |

Eleme çapı(mm) |

Boyut(mm) |

| BZP-600 |

0.12 |

520 |

740*600*560 |

| BZP-800 |

0.18 |

720 |

1010*800*600 |

| BZP-1000 |

0.18 |

890 |

1200*970*640 |

| BZP-1200 |

0.25 |

1090 |

1430*1700*700 |

| BZP-1500 |

0.25 |

1390 |

1780*1470*760 |

| Makine ihtiyacınıza göre özelleştirilebilir |

Şematik diyagram

Bu, müşteri tarafından özelleştirilmiş bir paketleme üretim hattıdır.

1. Tozsuz besleme 2. Malzeme eleme için doğrudan boşaltma eleği 3. Vidalı tozsuz taşıma 4. Karışık malzeme depolama kabı 5. Taşıma paketleme 6. Kantitatif paketleme

Detaylı gösterim

Uygulama

Paketleme ve Nakliye

Neden Bizi Seçmelisiniz

Hakkımızda

13 yıldır Eleme ve taşıma ekipmanları üretimi konusunda uzmanız. Çin'in titreşimli elek endüstrisinde ilk üçteyiz. Ve birçok büyük şirket için eşleştirme ve OEM yaptık. Dünyanın en iyi titreşimli elek üreticisi Sweco, ABD dahil olmak üzere, Çin bölgesi için OEM yaptık. Ve ürünlerimiz genellikle Avustralya, Tayland, Endonezya, Yeni Zelanda ve diğer ülkelere ihraç edilmektedir.Fabrikamızı ziyaret etmek için müşterileri veya bayileri ağırlıyoruz ve sizin için her şeyi ayarlayacağız. Fabrika adresimiz: Da Zhaoying Kasabası, Xinxiang Şehri, Henan Eyaleti, endüstriyel ve ticari ofisinin batısı.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!